The working principal of this valve is such that on the retraction of the piston, a “Negative Pressure” is created to “Pull Back” the material so as to achieve a quick cut off and or prevent dripping of material.

This valve is suitable for a wide range of material but is especially good for grease, silicone and pasty materials. Easy to maintain and operate, this valve is economical and robust.

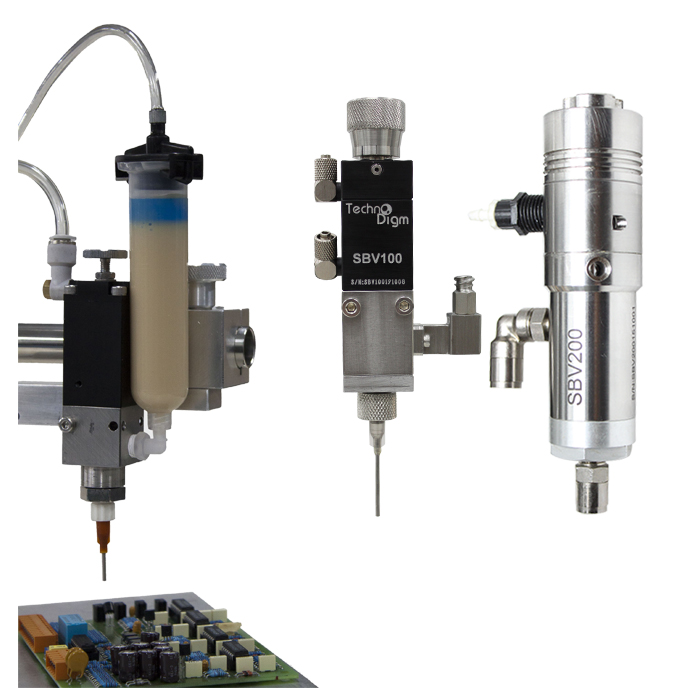

Specifications

| Model No. | SBV100 | SBV200 |

| Valve Type | Snuff Back | Snuff Back |

| Operating Air Pressure | 2 bar to 5 bar | 2 bar to 5 bar |

| Atomizing Air Pressure | N / A | N / A |

| Fluid Delivery Pressure | Max 7.0 bar | 1 bar to 150 bar (Max) |

| Minimum Shot Size | Ø 0.5 mm | Ø 1.0 mm |

| Driving Part Materials | ||

| Cylinder Body | Aluminium | 316 Stainless Steel |

| Cap | Aluminium | 316 Stainless Steel |

| Piston | SUS304 Stainless Steel | Hard Coated Aluminium |

| Check Body | Stainless Steel | 316 Stainless Steel |

| Wetted Part Materials | ||

| Chamber | Stainless Steel | Stainless Steel |

| CAP, CV Body | Stainless Steel | 316 Stainless Steel |

| Seals | Teflon | Viton / FKM / Fluorocarbon |

| Connecting Ports | ||

| Operating Air Inputs | M5 thread w/ push-in fitting for 6mm OD tube | 1 / 8 PT Female & M5 |

| Material Inlet | 1 / 8 NPT | 1 / 4 NPT Female |

| Material Outlet | White Nylon Luer Lock Adaptor 1 / 4 – 28 UNF | 1 / 4 NPT Female |

| Weight | 308g | 720g |