Defoamer and foam breaking agent (antifoam) are used to remove air bubbles that are produced during the process of resin mixing. Defoamer works by causing air bubbles to coalesce to the point where they are large enough to float harmlessly to the surface and break. Foam breaking agent works by altering the surface tension making the air bubbles unstable and easily broken.

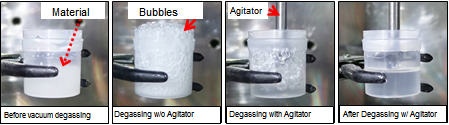

Generally, higher viscosity material is degassed using a vacuum chamber. The principle is that as pressure decreases, the air bubbles will expand and float to the resin surface and break. Degassing by vacuum chamber usually requires a significant amount of time and it tends to cause the resin to overflow from the container. The efficiency of vacuum degassing can be improved by supplementing it with an agitator. The positioning of the agitator is dependent on the resin viscosity. As air bubbles of low viscosity material are easier to expand, the agitator is position near the top surface of the resin causing the bubbles to collide and break. For high viscosity material, the agitator should be position near the bottom of the resin. This agitation will help the air bubbles to break the internal resistance and move to the surface to break eventually.